Logic NDT Solutions offers a multitude of Inspection Services, from Magnetic Particle Inspection to Liquid Penetrant Inspection... we have you covered!

Magnetic Particle Inspection

How it Works

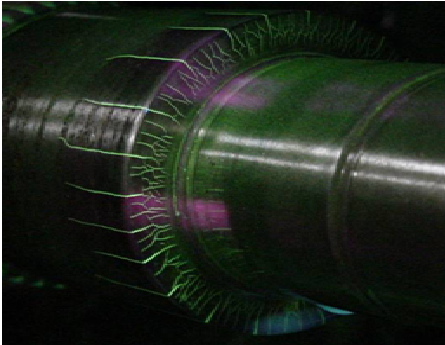

Magnetic Particle Inspection (MPI) is an investigative inspection technique used for finding surface/near surface defects in ferromagnetic material. Magnetic particle testing is a versatile inspection used for both field and shop applications. Magnetic particle testing works by magnetizing a ferromagnetic specimen using either a magnet or special magnetizing equipment. If the specimen has discontinuity, then the magnetic field flowing through-out the specimen is interrupted where leakage field occurs.

Finely milled iron particles coated with dye pigment are applied to the specimen, these are attracted to leakage fields and cluster to form indications directly over the discontinuity. This indication is then detected visually under proper lighting conditions.

Basic Procedures for Performing Magnetic Particle Testing

The basic procedure that is followed to perform Magnetic Particle testing consists of the following:

- Pre-cleaning of the Component

- Introduction of Magnetic Field

- Application of Magnetic Media

- Interpretation of Magnetic Particle Indications

It is essential for the particles to have an unimpeded path for migration to both strong and weak leakage fields. Therefore, the component in question should be clean and dry before beginning this inspection process. The presence of grease, oil, or scale can compromise the inspection. The introduction of the magnetic field can be done in a few ways, including the use of a permanent magnet, passing electrical current through the specimen or a coil of wire around said part, or through a central conductor running near the part.

Types of Magnetic Fields Used For Magnetic Particle Inspection

Establishing two types of magnetic fields within the specimen is possible.

Longitudinal: Longitudinal magnetic fields are produced using a magnetic coil or a permanent magnet called a Magnetic Particle Yoke.

Circular: Circular Magnetic Fields occur by passing current through the part, or by placing the part in a strong circular magnetic field.

Magnetic Particle Inspection can use wet or dry magnetic media. The dry method is more portable, but the wet method is generally more sensitive due to the liquid carrier giving the magnetic particles added mobility.

Liquid Penetrant Inspection

How it Works

Liquid Penetrant Inspection (LPI) is an inspection technique based on the properties of capillary action, the phenomenon of a liquid rising or climbing when confined to a small opening due to surface wetting properties of the liquid. We use this Penetrant testing to find surface breaking discontinuities on relatively smooth, nonporous surfaces.

Advantages of Liquid Penetrant Inspection

- Relatively easy to use

- Used on a wide range of material types

- Large areas or large volumes of parts/material can be inspected rapidly and at low cost

- Easily inspect Parts with complex geometries

- Indications are produced directly on the surface of the part providing a visual image of the anomaly

- Using Aerosol spray cans make equipment very portable

A partial list of these certifications/techniques includes American Petroleum Institute (API), SNT-TC-1A, and DS-1 (TH Hill) Standards.

Basic Procedures for Liquid Penetrant Inspection

The basic procedure necessary for carrying out Liquid Penetrant Inspection consist of the following:

Rolled Products: Penetrant identifies anomalies (cracks, seams or laminations)

Castings: Cold shuts, hot tears, porosity, blow holes or shrinkage

Forgings: Illuminating cracks, laps or external bursts

Welds: To identify cracks, porosity, undercut, overlap, lack of fusion or lack of penetration

Rotary Shouldered Threaded Drilling Tools: To identify cracks, corrosion pitting, mechanical damages on outside diameters, or inside diameters, and internal/external washing from fluid erosion

The Two Main Types of Liquid Penetrant Inspection

There are two main types of Penetrant, Fluorescent or Visible. Within either of these methods, there are several other practices including water washable, postemulsifiable-lipophilic, solvent removal and postemulsifiable-hyperdrophilic. There are six main steps involved with penetrant testing:

- Pre-Clean.

- Application of Penetrant Material.

- Dwell Time/Penetrant Removal.

- Developer Application

- Inspection/Evaluation.

- Post Clean.

Visual Inspection

Visual inspection technique is used within multiple industries. All NDT techniques are based on interpreting visual anomalies to determine test specimen soundness as detailed by the code or specifications to which the test is performed. However, specific industries require a variety of visual inspection certifications to inspect their specific equipment.

A partial list of these certifications/techniques includes; American Petroleum Institute (API), SNT-TC-1A, ASNT, CGSB, and DS-1 (TH Hill) Standards.