Shot Peening

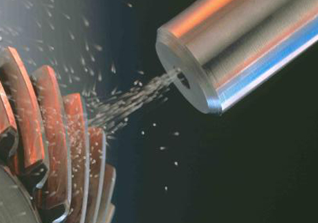

Our technicians perform Shot Peening on a number of different tools using several methods of media with varying levels of intensity.

Shot Peening is the process in which we blast the surface of material in order to alter the surface composition, it becomes more resistant to cracking and less likely to fail due to stress corrosion.

In order to ensure your product is Shot Peened appropriately, we will review your specific Customer Requirements. Logic NDT Solutions will ensure we have the appropriate media loaded (Ceramic/Glass/110/330/550/780 Steel NM) and perform an Almen test to ensure our intensity is set to the appropriate level as per our clients needs.

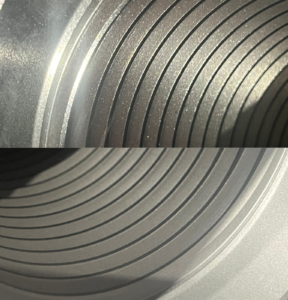

The benefits results in longer lasting tools and equipment, a decrease in galled threads and overall savings on costly tool replacement and repairs. Just look at this before and after!

Allow Logic NDT Solutions Ltd to take care of Cleaning, Masking, Blasting, Decontaminating, and returning of your tools!