Our Services

Logic NDT Solutions Ltd offers an array of professional oilfield services, learn more about our services and the processes we follow below!

Magnetic Particle Inspection | Liquid Penetrant Inspection | Visual Inspection

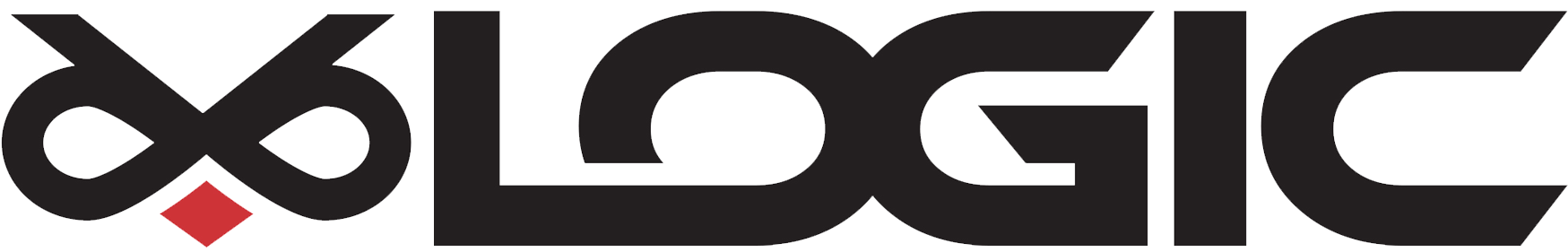

Magnetic Particle Inspection

How it Works

Magnetic Particle Inspection (MPI) is an investigative inspection technique used for finding surface/near surface defects in ferromagnetic material. Magnetic particle testing is a versatile inspection used for both field and shop applications. Magnetic particle testing works by magnetizing a ferromagnetic specimen using either a magnet or special magnetizing equipment. If the specimen has discontinuity, then the magnetic field flowing through-out the specimen is interrupted where leakage field occurs.

Magnetic particle testing works by magnetizing a ferromagnetic specimen using either a magnet or special magnetizing equipment. If the specimen has discontinuity, then the magnetic field flowing through-out the specimen is interrupted where leakage field occurs.

Finely milled iron particles coated with dye pigment are applied to the specimen, these are attracted to leakage fields and cluster to form indications directly over the discontinuity. This indication is then detected visually under proper lighting conditions.

Basic Procedures for Performing Magnetic Particle Testing

The basic procedure that is followed to perform Magnetic Particle testing consists of the following:

- Pre-cleaning of the Component

- Introduction of Magnetic Field

- Application of Magnetic Media

- Interpretation of Magnetic Particle Indications

It is essential for the particles to have an unimpeded path for migration to both strong and weak leakage fields. Therefore, the component in question should be clean and dry before beginning this inspection process. The presence of grease, oil, or scale can compromise the inspection. The introduction of the magnetic field can be done in a few ways, including the use of a permanent magnet, passing electrical current through the specimen or a coil of wire around said part, or through a central conductor running near the part.

Types of Magnetic Fields Used For Magnetic Particle Inspection

Establishing two types of magnetic fields within the specimen is possible.

Longitudinal: Longitudinal magnetic fields are produced using a magnetic coil or a permanent magnet called a Magnetic Particle Yoke.

Circular: Circular Magnetic Fields occur by passing current through the part, or by placing the part in a strong circular magnetic field.

Magnetic Particle Inspection can use wet or dry magnetic media. The dry method is more portable, but the wet method is generally more sensitive due to the liquid carrier giving the magnetic particles added mobility.

Liquid Penetrant Inspection

How it Works

Liquid Penetrant Inspection (LPI) is an inspection technique based on the properties of capillary action, the phenomenon of a liquid rising or climbing when confined to a small opening due to surface wetting properties of the liquid. We use this Penetrant testing to find surface breaking discontinuities on relatively smooth, nonporous surfaces.

Basic Procedures for Liquid Penetrant Inspection

The basic procedure necessary for carrying out Liquid Penetrant Inspection consist of the following:

Rolled Products: Penetrant identifies anomalies (cracks, seams or laminations)

Castings: Cold shuts, hot tears, porosity, blow holes or shrinkage

Forgings: Illuminating cracks, laps or external bursts

Welds: To identify cracks, porosity, undercut, overlap, lack of fusion or lack of penetration

Rotary Shouldered Threaded Drilling Tools: To identify cracks, corrosion pitting, mechanical damages on outside diameters, or inside diameters, and internal/external washing from fluid erosion

The Two Main Types of Liquid Penetrant Inspection

There are two main types of Penetrant, Fluorescent or Visible. Within either of these methods, there are several other practices including water washable, postemulsifiable-lipophilic, solvent removal and postemulsifiable-hyperdrophilic. There are six main steps involved with penetrant testing:

- Pre-Clean.

- Application of Penetrant Material.

- Dwell Time/Penetrant Removal.

- Developer Application

- Inspection/Evaluation.

- Post Clean.

Advantages of Liquid Penetrant Inspection

- Relatively easy to use

- Used on a wide range of material types

- Large areas or large volumes of parts/material can be inspected rapidly and at low cost

- Easily inspect Parts with complex geometries

- Indications are produced directly on the surface of the part providing a visual image of the anomaly

- Using Aerosol spray cans make equipment very portable

A partial list of these certifications/techniques includes American Petroleum Institute (API), SNT-TC-1A, and DS-1 (TH Hill) Standards.

Visual Inspection

Visual inspection technique is used within multiple industries. All NDT techniques are based on interpreting visual anomalies to determine test specimen soundness as detailed by the code or specifications to which the test is performed. However, specific industries require a variety of visual inspection certifications to inspect their specific equipment.

require a variety of visual inspection certifications to inspect their specific equipment.

A partial list of these certifications/techniques includes; American Petroleum Institute (API), SNT-TC-1A, ASNT, CGSB, and DS-1 (TH Hill) Standards.

Connection Thread & Seal Repair | Machine Shop Services | Hard-Band & Mud-Ring Repair | Window Cutting & Tools Serialization

Connection Thread & Seal Repair

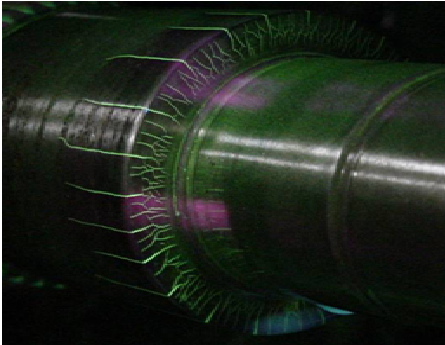

Logic NDT Solutions Ltd collaborates with highly-trained and authorized specialists to complete tasks as per specification. Our experts verify LOGIC’s Thread and Seal Repair of rotary shouldered connections during the process of visual inspection. In many drilling applications, thread and seals can become damaged. These are classified into two types: repairable on-site, and unfixable onsite damages; require a repair or re-cut at a machine shop.

Machine Shop Services

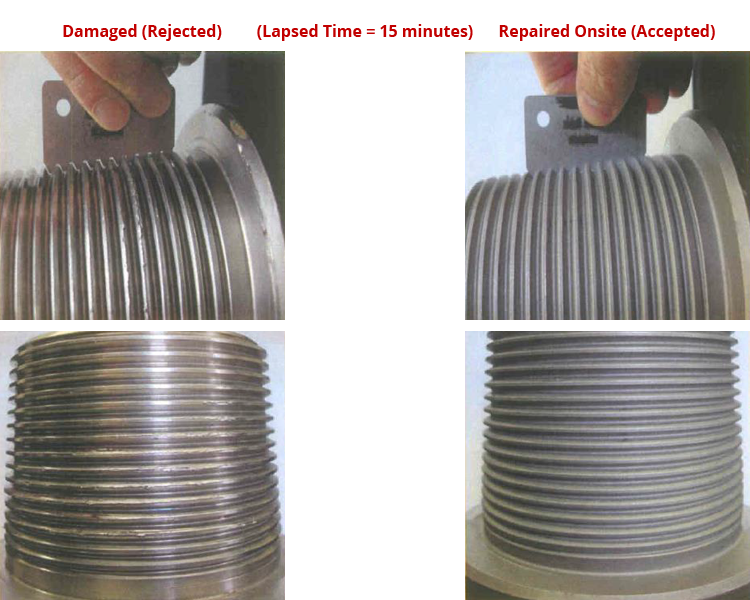

Threads and Seals may become damaged, cracked, exposed to corrosion-inhibited pitting, or washed due to fluid erosion. Due to the material sustaining cracks, additional evaluation may be required depending on the material’s nature. Non-ferrous materials require Liquid Penetrant evaluations, while ferrous materials undergo Magnetic Particle evaluations.

LOGIC offers three types of Machine Shop Services to our valued clients:

- Manufacturing of tools or rotary shouldered connections

- Re-cut rotary shouldered connections or a face

- Chase repair services of a rotary shouldered connection of shoulder

All these services require transportation to or from our critical provider’s facility, LOGIC will verify the proper machining is followed by conducting a final inspection before delivery is returned to the customer. Below, we have some examples of damages that would require machine shop repair:

Hard-Band & Mud-Ring Repair

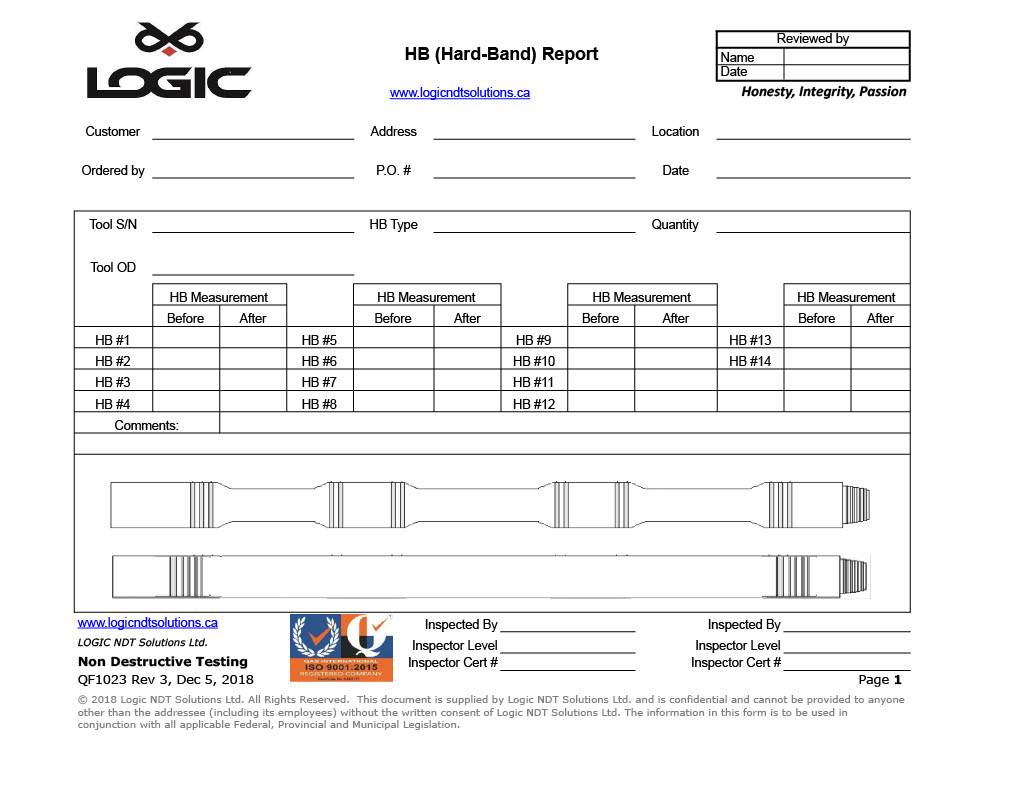

Our specialists determine the Hard-Banding servicing of drilling during the visual segment of the inspection process. The size (width) and type (PTA or Laser Clad) of hard-banding are provided to us by our clients. We monitor the before and after measurements by issuing a Hard-Band Report given to the provider by Logic NDT Solutions on behalf of the customer.

by issuing a Hard-Band Report given to the provider by Logic NDT Solutions on behalf of the customer.

Once completed, the customer receives a copy of the Hard-Band Report, and LOGIC keeps a digital copy for reference if required later.

Window Cutting & Tools Serialization

Logic NDT Solutions Ltd offers professional window cutting and tool serialization services on a wide scale to ensure our clients receive premium quality services. We use the best experts in this field with state of the art machinery to provide cutting-edge tool serialization services.

Revolutionizing Hardbanding with Cold Metal Transfer (CMT)

What is CMT?

At Logic NDT Solutions, we use Cold Metal Transfer (CMT) welding technology to bring you unmatched precision. CMT is a cutting-edge welding method that operates at a lower heat input, resulting inreduced distortion, minimal splatter, and exceptional control.

With CMT, we ensure clean, high-quality welds, making it an ideal choice for applications that demand precision and efficiency. Whether it’s non-magnetic collar hardbanding, steel component welding/inspection, or any other welding requirements, our CMT process delivers superior results.

Take a look at our new Logiband NM Hardbands and the Sample Reports to get an depth understanding of our process and results! Also available for our Logiband NC (Steel)!

Test pieces are available upon request, contact our team here! Experience the difference with Logic NDT Solutions and our CMT welding expertise, where precision and excellence meet in every joining.

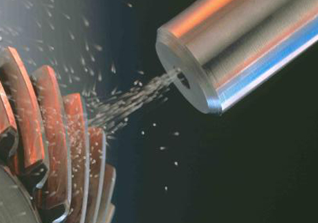

Shot Peening

Our technicians perform Shot Peening on a number of different tools using several methods of media with varying levels of intensity.

Shot Peening is the process in which we blast the surface of material in order to alter the surface composition, it becomes more resistant to cracking and less likely to fail due to stress corrosion.

In order to ensure your product is Shot Peened appropriately, we will review your specific Customer Requirements. Logic NDT Solutions will ensure we have the appropriate media loaded (Ceramic/Glass/110/330/550/780 Steel NM) and perform an Almen test to ensure our intensity is set to the appropriate level as per our clients needs.

The benefit of Shot Peening results in longer lasting tools and equipment, a decrease in galled threads and overall savings on costly tool replacement and repairs.

Allow Logic NDT Solutions Ltd to take care of Cleaning, Masking, Blasting, Decontaminating, and returning of your tools!

Float Valve Supply | Repair Kits & Servicing

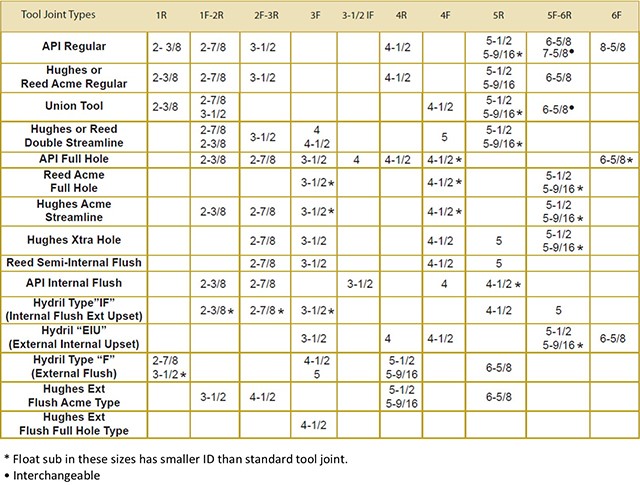

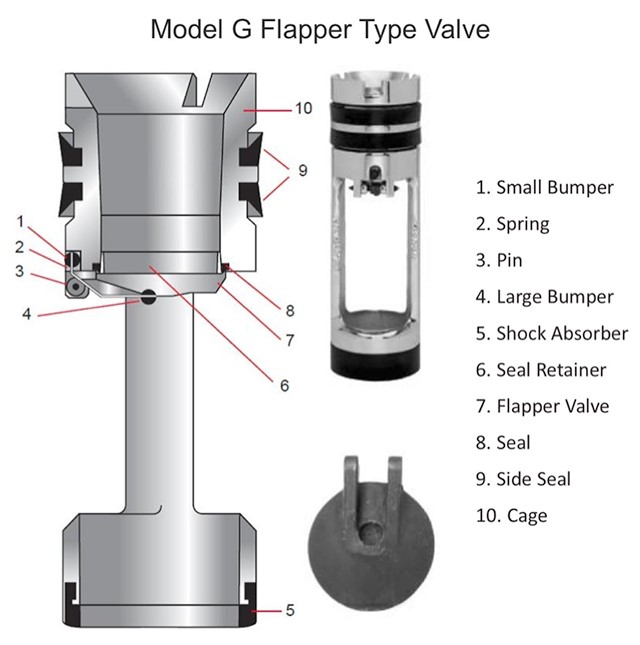

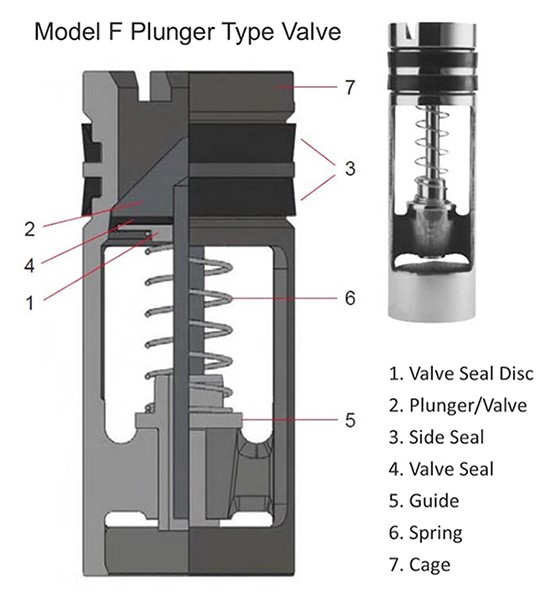

Logic NDT Solutions’ maintains a comprehensive Float Valve inventory, offering Model F Plunger Style and Model G Flapper Style float valves in both ported and non-ported configurations. We provide various sizes and options, providing float valves for production, drilling, and many other processes.

Float Valve Specification Guide

Our specialized service includes collecting used Float Valves and using LOGIC’s Rubber Seal and Metal Repair Kit, so they may be rebuilt at our facility, saving our clients time and money. We ensure seamless fixes and an extended life for your valves, including a complete detailed report with every repair.

The following products are available in Standard Service and Hi-Temp / NACE assemblies:

- Flapper – Full Flow

RATED OPERATING PRESSURE 7,500 WP

The Flapper style valve features a cast flapper, offering quick and unrestricted full flow. This Model F Flapper Type (Open Valve) includes a specially designed flapper that swiftly opens for an unrestricted bore, ideal for highly abrasive fluids. It instantly closes when circulation stops, preventing cuttings from entering the drill string and plugging the bit. When the first joint is raised out of the hole, the valve opens, ensuring the first joints drain and are not pulled wet. The Flapper Type complements primary blowout prevention equipment, delivering comprehensive internal pressure control.

- Plunger Type

RATED OPERATING PRESSURE 7,500 WP

The Plunger type valve offers positive and instantaneous shut-off, offering both economy and durability during drilling operations. The piston stops flow-back, keeping cuttings out of the drill sting, and its interchangeable parts enhance convenience. Withstanding high and low pressure, the durable Model F ensures continuous control of fluid flow, making it the most economical choice for normal drilling operations, available in all sizes.

Tool Management Services

Tool Management is an equally important component at Logic, which separates us from our competitors in the fact that we offer a “one stop shop”. At Logic NDT Solutions Ltd we broker all repair and maintenance required services for both used and new drilling tools for our valued customers.

Our tool management services are broken down but not limited to:

- Inspection Services

- Repair On & Offsite Services

- Hard-Band Services

- Storage Services

- Shipping and Receiving Services

- In Town Trucking, and between Calgary & Nisku Services

- Tool Rentals

Collar Tubs – For High Volume Storage, 100k lbs Capacity

Tree Racks – Drilling Tool Storage / Job Pick Rack

Window Cutting & Tool Serialization

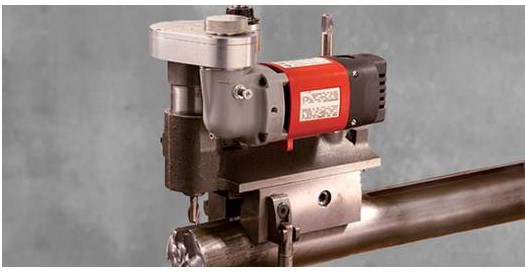

Having the ease and ability to cut windows and serialize assets helps maintain organization for tool management. Logic NDT Solutions Ltd can cut windows and stamp all sizes of tubulars ranging from 3.5″ OD up to 11″ OD and can cut up to 1″x 8″ window slots with our portable milling machine.

Compact & Powerful

Compact, rugged, portable milling machine for on-site keyway and other milling jobs.

- Self-centering and self-aligning V-base

- Needs only 1.5 inches (38.1 mm) of shaft for clamping

- Clamps on shafts up to 10.5 inches (266.7 mm) diameter with optional chain clamp

- Slotted V-base allows you to cut right to the end of the shaft

Efficient Operations with High Quality Components

- Vertical & Horizontal travel via hand crank

- Dovetail ways for accurate cutting action

- Standard Weldon-type spindle accepts 5/8 inch end mills, or 16 mm shank end mills on metric machines

- Precision Acme thread leadscrew with roller thrust bearings

- Zeroing-type vertical adjustment dial calibrated to control cutter depth in 0.001 inch (0.1 mm) increments

- Sealed aluminum alloy gear box permits operation at any angle

- Precision ground quill housing ensures smooth operation

Engineered Structural NDT

Our commitment to precision inspections remains unwavering. With a blend of advanced technology and expert analysis, we offer a comprehensive selection of inspection techniques. LOGIC’s services encompass a wide range of structures, ensuring every inch meets the highest standards of safety and performance.

At Logic NDT Solutions, we go beyond traditional inspection. We embrace a commitment to excellence that defines our approach, with an aim to revolutionize the way you perceive structural integrity inspection.

Contact us today, to learn more about our services, and what LOGIC can do you for you!

Handling Equipment Inspection

From cranes that shoulder heavy loads to conveyors that keep industries moving, we leave no corner un-examined. Our methods are meant to inspect the intricate mechanisms of your equipment, uncovering potential vulnerabilities that might be beneath the surface.

At the core of our approach lies a commitment to delivering actionable insights. Our team of experienced professionals merges technology with years of expertise to provide you with a comprehensive understanding of your equipment health.