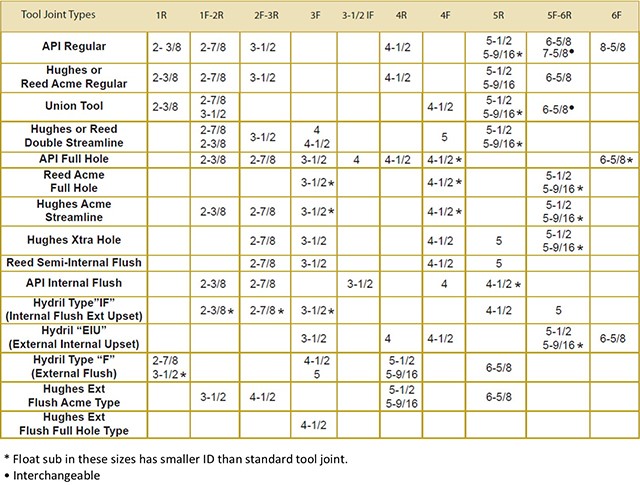

Logic NDT Solutions’ maintains a comprehensive Float Valve inventory, offering Model F Plunger Style and Model G Flapper Style float valves in both ported and non-ported configurations. We provide various sizes and options, providing float valves for production, drilling, and many other processes.

Float Valve Specification Guide

Our specialized service includes collecting used Float Valves and using LOGIC’s Rubber Seal and Metal Repair Kit, so they may be rebuilt at our facility, saving our clients time and money. We ensure seamless fixes and an extended life for your valves, including a complete detailed report with every repair.

The following products are available in Standard Service and Hi-Temp / NACE assemblies:

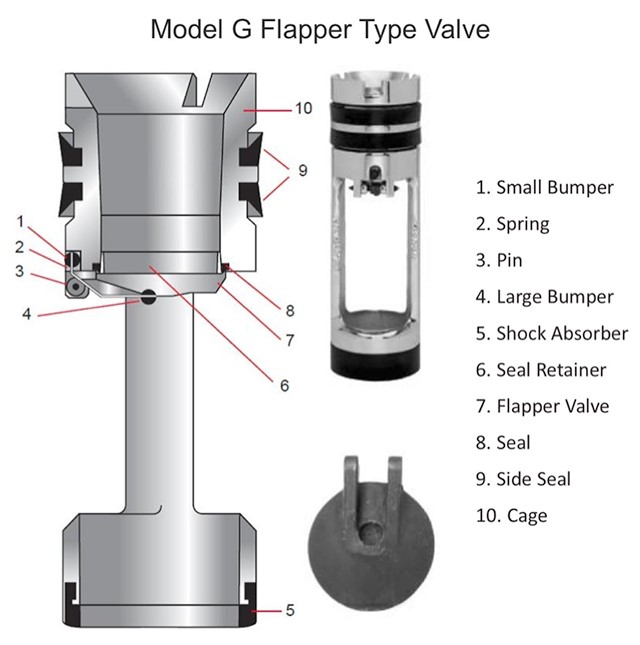

- Flapper – Full Flow

RATED OPERATING PRESSURE 7,500 WP

The Flapper style valve features a cast flapper, offering quick and unrestricted full flow. This Model F Flapper Type (Open Valve) includes a specially designed flapper that swiftly opens for an unrestricted bore, ideal for highly abrasive fluids. It instantly closes when circulation stops, preventing cuttings from entering the drill string and plugging the bit. When the first joint is raised out of the hole, the valve opens, ensuring the first joints drain and are not pulled wet. The Flapper Type complements primary blowout prevention equipment, delivering comprehensive internal pressure control.

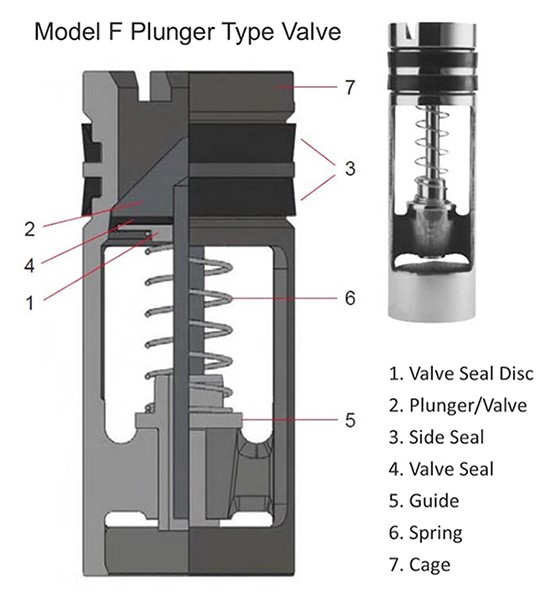

- Plunger Type

RATED OPERATING PRESSURE 7,500 WP

The Plunger type valve offers positive and instantaneous shut-off, offering both economy and durability during drilling operations. The piston stops flow-back, keeping cuttings out of the drill sting, and its interchangeable parts enhance convenience. Withstanding high and low pressure, the durable Model F ensures continuous control of fluid flow, making it the most economical choice for normal drilling operations, available in all sizes.