Your go-to for Tool Repair Services, trust in Logic NDT Solutions for reliable and efficient repairs to keep your equipment performing at its best!

Connection Thread & Seal Repair

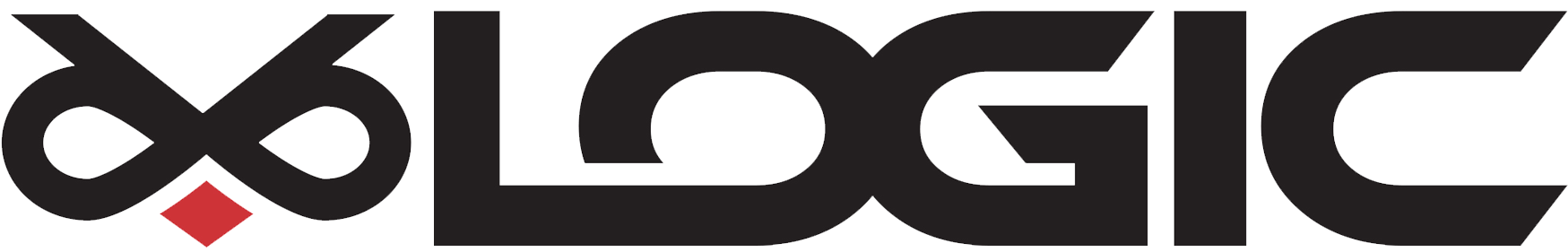

Logic NDT Solutions Ltd collaborates with highly-trained and authorized specialists to complete tasks as per specification. Our experts verify LOGIC’s Thread and Seal Repair of rotary shouldered connections during the process of visual inspection. In many drilling applications, thread and seals can become damaged. These are classified into two types: repairable on-site, and unfixable onsite damages; require a repair or re-cut at a machine shop.

Machine Shop Services

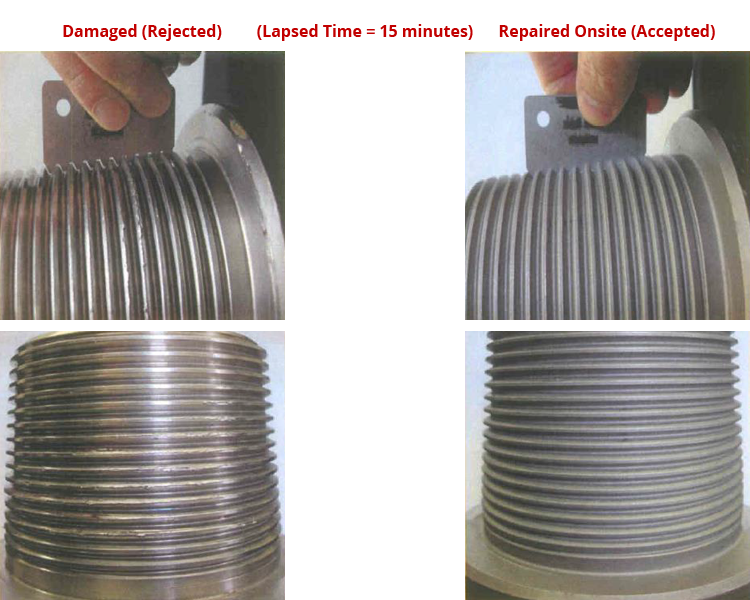

Threads and Seals may become damaged, cracked, exposed to corrosion-inhibited pitting, or washed due to fluid erosion. Due to the material sustaining cracks, additional evaluation may be required depending on the material’s nature. Liquid Penetrant evaluations are required for non-ferrous materials, while Magnetic Particle evaluations are conducted for ferrous materials.

LOGIC offers three types of Machine Shop Services to our valued clients:

- Manufacturing of tools or rotary shouldered connections

- Re-cut rotary shouldered connections or a face

- Chase repair services of a rotary shouldered connection of shoulder

All these services require transportation to or from our critical provider’s facility, LOGIC verifies proper machining is followed by conducting a final inspection before delivery is returned to the customer. Below, we have some examples of damages that would require machine shop repair:

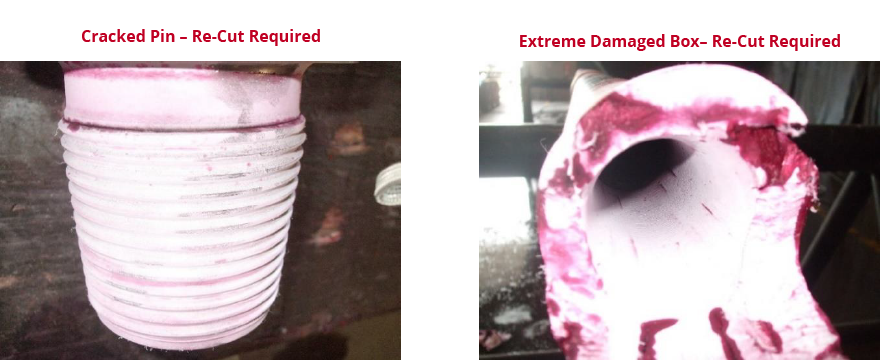

Hard-Band & Mud-Ring Repair

Our dedicated specialists assess the Hard-Banding servicing of drilling during the visual inspection process. The size (width) and type (CMT, PTA, Laser Clad) of hard-banding are provided to us by our clients. We monitor the before and after measurements by issuing a Hard-Band Report to the provider on behalf of the customer.

by issuing a Hard-Band Report to the provider on behalf of the customer.

Upon completion, the customer receives a copy of the Hard-Band Report, and LOGIC keeps a digital copy for reference if required later. No matter what Tool Repair Services are required, LOGIC ensures communication is clear and thorough!